S4000

Dual Fuel Systems for Stationary Diesel Engines

The Science Behind APG’s Dual Fuel Technology for Stationary Applications

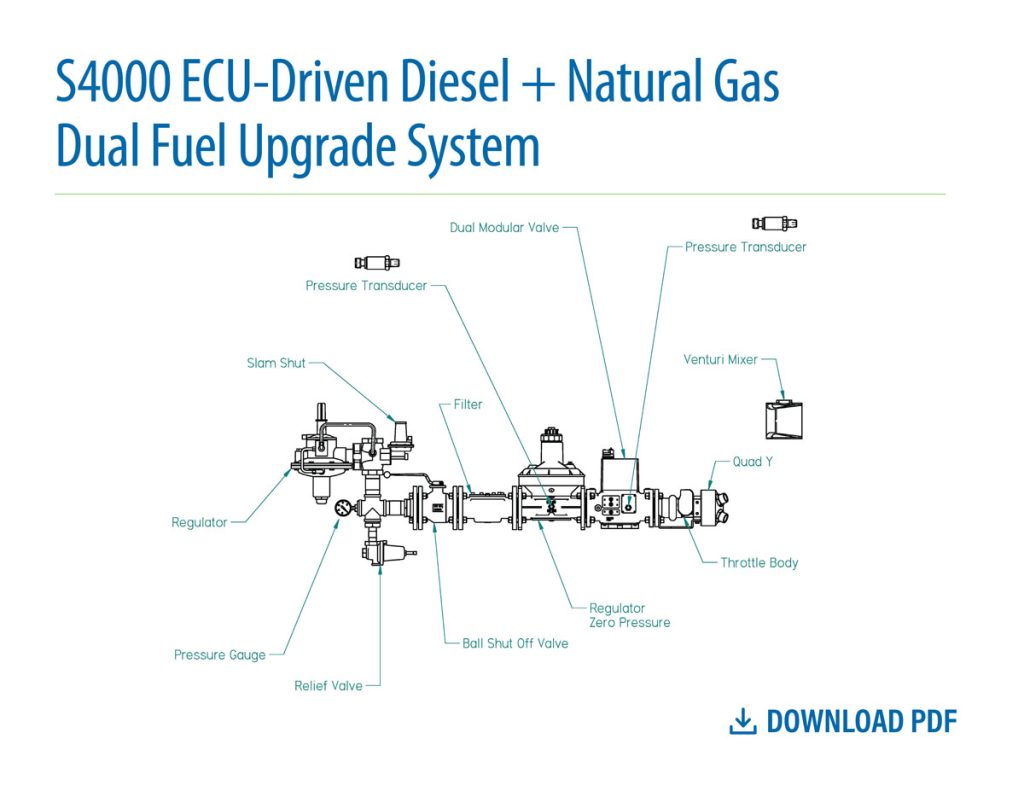

American Power Group’s Dual Fuel Technology is an EPA-approved, aftermarket upgrade system that seamlessly meters a secondary fuel into the induction system of stationary diesel engines. Applications include stationary and emergency power generation, data centers, fuel distribution and more, providing fleet owners with a solution that reduces both costs and greenhouse gas emissions.

APG’s efficient and reliable systems do not interfere with the OEM diesel engine integrity or impact the base engine warranty, and owners can switch back to diesel-only operation at any time.

Our Dual Fuel Technology is a negative pressure system that uses the diesel engine’s governor to reduce diesel fuel usage, as the higher energy value of the secondary fuel mixed with air is recognized at the point of compression flashpoint. Remaining diesel fuel provides proper engine lubricity and helps retain the power and torque of the base engine.

Depending on the secondary fuel source, owners can expect an average range of 40–55% displacement, with potential peak displacement up to 75%. Fleet owners have seen fuel savings up to 40% and can achieve their environmental goals by choosing carbon-neutral or carbon-negative fuel sources.

- No loss of power and torque

- Fuel savings impact the bottom line

- Utilize domestic fuel sources

- EPA Memorandum 1A compliant

- Meet environmental goals

- Reduce emissions with carbon-neutral and carbon-negative fuels

Get Started

Download our Questionnaire

Answer a few questions to learn how APG can help improve your heavy-duty diesel operation with our Dual Fuel Technology.